China Hats Wholesale: From Factory Sourcing to Import Compliance Ultimate Guide 2025

Quick Jump to The Topic You Are Interesting in by Click Below Highlighted Heading:

- Decoding the Hat Price – Why One Hat Costs $1.50 and Another $12

- The Sourcing Journey – Pinpointing Your Ideal Production Partner

- Hats Customization – The Non-Negotiable Tech Pack

- The Risk Shield – Professional QC & Secure Payments

- The U.S. , EU and Australia Hat Import Checklist: Staying Out of Trouble

- Optimizing Logistics & Calculating True Cost

Close view of a factory beret sample showroom wall with LED-lit, arched shelving running floor to ceiling. The top rail shows mannequin headforms wearing sample berets; shelves below hold neatly arranged, color-sorted stacks in pastels, brights, and neutrals. Constructions include wool felt, knit and woven berets, all brimless, flat-crown styles. Uniform thickness and crown diameter indicate quality-controlled, high-capacity stock suitable for bulk orders, OEM/ODM, private-label branding, embroidery or logo placement.

Beyond Cheap: A Practical Guide to Sourcing Hats in China

For global fashion brands, drop-shipping, ambitious startups, and established retailers, sourcing hats from China is not just an option; it’s fundamental to staying competitive. However, a successful import strategy is built on far more than finding the lowest price on Alibaba. It really comes down to a few key things: truly understanding how manufacturing works there, keeping a close eye on product quality, always following international rules, and building strong relationships with your factories.

This guide shares what actually works, not the generic advice you’ll find in every other article. We will take you inside the factory gates, adopting the perspective of a manufacturer to decode the complex relationship between price and quality. This is not just another “how-to” article; it is a comprehensive, battle-tested operational playbook covering everything from finding factory to final delivery. Whether you’re launching a niche brand with a 100-piece custom order or a major retailer planning a mass-market production run, this guide gives you the expert know-how to avoid expensive mistakes, make better profits, and build a solid supply chain you can truly rely on.

At a Glance: Your Strategic Toolkit

- Price vs. Value Decoded: Understand precisely why one cap has an Ex-work price of $0.65 while another is $12.00+. We will break down how materials, construction, and quality control determine the final cost.

- The Sourcing Map: Learn to pinpoint the ideal manufacturing partner by navigating the specialized production hubs of Guangdong, Zhejiang, and Fujian based on your product’s market position. We’ll also take you on a virtual tour of the Yiwu International Trade City with exclusive, on-the-ground sourcing tactics.

- The Production Blueprint: Master the single most critical document in custom manufacturing—the “Tech Pack”—to ensure your design vision is executed with absolute precision.

- The Risk Shield: Implement a professional, three-stage Quality Control (QC) protocol and adopt secure payment structures to safeguard your investment. This normally a sourcing agent can help with.

- The Compliance Gauntlet: Navigate the complex web of U.S. import regulations, including textile labeling laws and CPSIA standards for children’s products, to prevent customs troubles and legal risks.

Chapter 1: Decoding the Price – Why One Hat Costs $1.50 and Another $12

Before you even think about contacting a supplier, your first objective is to become an educated buyer. In China, the price spectrum for headwear is vast, ranging from under $1.50 to over $12.00 per unit. This difference is not arbitrary; it’s a direct reflection of real differences in materials, how the hats are made, and the quality checks they go through.

1.1 The Tiered System of Hat Quality & Pricing

An experienced factory doesn’t just sell “hats”; they manufacture products across distinct quality tiers. Understanding this framework is the first step toward making a smart buying decision.

| Quality Tier | Price Range (Per Unit) | Key Material & Construction Characteristics of Hats | Target Market Application |

|---|---|---|---|

| Entry-Level / Promotional | $0.65 – $2.00 | • Fabric: 220-260 GSM (Grams per Square Meter) basic cotton or polyester mesh. • Hardware: Standard plastic snap closures. • Workmanship: Standard machine embroidery with limited color matching precision. | Promotional giveaways, event merchandise, and highly cost-sensitive, low-end retail. |

| Mid-Range / Commercial | $2.00 – $5.00 | • Fabric: 280-320 GSM combed cotton or premium poly-cotton blends. • Hardware: Metal buckles or higher-grade plastic adjusters. • Workmanship: Pantone color matching for accuracy, higher stitch-density embroidery. | Retail brands, corporate apparel, and the majority of mainstream e-commerce businesses. |

| Premium / Boutique / Brand | $5.00 – $7.50+ | • Fabric: 340+ GSM heavy brushed cotton, performance fabrics (e.g., moisture-wicking, UV-resistant). • Hardware: Custom-molded metal hardware, genuine leather straps. • Workmanship: Precision color matching, complex decoration techniques (e.g., 3D embroidery, woven patches, appliqué). | High-end fashion labels, designer brands, and professional athletic apparel. |

* if you are reviewing this comparison table via a mobile phone and the table doesn’t display completely, simply swipe the table to the right to see the rest.

Expert Tip: Never ask a potential supplier, “How much for a hat?” A professional inquiry sounds like this: “What is your unit price for 500 six-panel baseball caps using 300 GSM combed cotton, with a metal buckle and 3D embroidery?” This signals your expertise and ensures you receive a serious, accurate quotation.

1.2 Beyond the Fabric: Other Factors That Shape Your Price

Beyond the primary materials, several other factors significantly influence your final cost:

- Construction Techniques: The internal structure of the cap—such as the use of hard buckram to reinforce the front panels—determines its shape and longevity. More complex stitching and multi-panel designs (e.g., 5-panel vs. 6-panel) increase labor costs.

- Quality Control (QC): You can specify the intensity of the inspection process. A basic random check is cheapest, whereas a comprehensive inspection following an AQL 2.5 international standard will add cost but provide maximum quality assurance.

- Compliance & Certifications: If your product requires certifications for specific standards like GRS (Global Recycled Standard) or a BSCI (Business Social Compliance Initiative) factory audit, the costs associated with these will be included in your quote.

Chapter 2: The Sourcing Journey – Pinpointing Your Ideal Hat Production Partner

Once you have a solid understanding of your product, the next phase is to identify a manufacturer capable of bringing your vision to life. China’s hat / cap industry is highly regionalized, with different areas offering distinct advantages.

2.1 China’s Headwear (Hat, Cap, Visor) Manufacturing Map

A strategic sourcing plan involves targeting the right region for your specific product needs, not casting a wide, inefficient net:

- Guangdong Province (Guangzhou, Dongguan): The Hub of High-End Fashion & Brand Manufacturing. This region is home to China’s most sophisticated craftsmanship, cutting-edge designs, and premium material suppliers. If your brand is built on superior quality and intricate detail, this is your primary destination. Be prepared for higher prices and Minimum Order Quantities (MOQs).

- Zhejiang Province (Yiwu, Ningbo): The Hub of Flexibility & Value. Factories in Zhejiang offer an exceptional balance of quality and price. Known for its vast export infrastructure, flexible MOQs (often starting at 100-300 pieces, if in Yiwu Market, it can be as low as 12 pieces), and remarkable production speed, this region is the ideal launchpad for most startups and small-to-medium-sized businesses.

Factory-direct hat wholesaler in Yiwu Market, District 4. Color-sorted bucket hats and seasonal styles displayed in a clean showroom for buyers and importers.

This photo shows a hat wholesaler’s factory showroom inside Yiwu International Trade City, District 4. Floor-to-ceiling illuminated shelving lines the storefront, neatly stacked with bucket hats arranged by color—from neutrals like beige, gray, and brown to bright tones such as yellow, pink, teal, and red. Additional wall bays display tightly packed columns of folded hats, highlighting consistent sizing and bulk inventory suited for exporters and retailers. A wide, glossy corridor with wood-slat ceiling panels leads past neighboring hat shops, and several shoppers can be seen in the distance. The store layout communicates high stock availability, fast order fulfillment, and OEM/ODM potential typical of Yiwu’s hat manufacturing supply chain.

- Shandong Province (Qingdao): The Global Major Manufacturing Region for Baseball Cap. While other regions offer specialization, Shandong Province, and specifically the city of Qingdao, has established itself as a global-scale production hub, particularly for baseball and sports caps. The town of Ligezhuang in Jiaozhou is known as “China’s hometown of hats,” producing an estimated 500 million hats annually and accounting for half of the nation’s total output of sports hats. Some reports indicate the town is responsible for one-third of the world’s baseball caps. This immense scale is supported by a hyper-localized and complete industrial ecosystem, where everything from raw materials and accessories to specialized machinery and packaging is readily available.

- Fujian Province (Xiamen, Fuzhou, Quanzhou, Jinjiang): The Engine of Sportswear and High-Volume Production: For brands focused on athletic, performance, and casual headwear, Fujian Province is the premier destination. The region’s manufacturing ecosystem is engineered for the efficient, large-scale production of functional and durable hats, including baseball caps, visors, trucker hats, and other sport-specific styles. Its key strengths are competitive pricing at volume and deep expertise in working with performance materials.

2.2 On-the-Ground Intelligence: A Deep Dive into the Yiwu Hat Market

For buyers wishing to dive deep into the market, the Yiwu International Trade Market (often called Yiwu Futian Market or just Yiwu Market) is an essential destination.

In District 4 of Yiwu International Trade City, the hat section spans No. 18 through No. 30 streets. Overhead “Hat” signs and clear street numbers guide buyers along aisles lined with cap and hat wholesalers, with the South Hall nearby—ideal for visitors planning an efficient sourcing route.

- Precise Location: Hat and related head-wear accessories are concentrated in 2nd Floor of District 4 of Yiwu International Trade Market. Knowing this saves invaluable time.

- Price & MOQ Advantage: Yiwu’s strength lies in its incredibly competitive pricing and flexibility. Basic baseball caps can be sourced for as little as $0.65 – $2.00 per piece, and many vendors will accept MOQs starting at just 12 units (a pack = 12 pieces).

Inside a hat wholesaler in the District 4 hats section (2F) of Yiwu International Trade City. Wall-to-wall summer styles—children’s bucket hats, woven straw hats, and adjustable sun visors—ideal for buyers sourcing bulk orders at Street 18

- Actionable Sourcing Tactics:

- Bring Cash: Many vendors prefer cash transactions, especially for smaller orders. This allows you to pay on the spot and take samples or in-stock items with you immediately.

- Hire a Translator / Agent: Although many vendors speak some English, hiring a local translator or agent is key to getting the best deal and making sure all your product details are understood perfectly. If you need a sourcing agent / translator, we can help you with

- Negotiate Friendly: While bargaining is a normal part of the process, always remember to be respectful. A friendly and professional attitude will take you much further than aggressive haggling.

- Collect Samples: Always get a physical sample in your hands and check it carefully before you commit to a big order.

2.3 Vetting Hat Suppliers Online: A Strategic Framework

B2B platforms like Alibaba and Made-in-China.com are powerful tools, but they must be navigated with a clear strategy.4

- Initial Screening: Use platform filters to narrow your search. A widely respected rule of thumb among experienced importers is to disregard any supplier with less than 3 years of “Gold Supplier” status on Alibaba. A longer tenure is often an indicator of stability and reliability.

- Deep Verification: Move beyond the profile page. Request and verify the following documents from any potential partner:

- Business License: To confirm their legal registration.

- Export License: To ensure they are authorized to export directly.

- Factory Audit Reports: Look for certifications like BSCI (for social compliance) or ISO 9001 (for quality management systems).4

- Expert Tip: Insist on a live, real-time video tour of the factory floor. This is far more revealing than a polished, pre-recorded promotional video and helps verify they are a genuine manufacturer, not just a trading company.

2.4 Strategic Timing: The Seasonal Sourcing Calendar For Hats Order

From my past experience, I’ve seen some brands make the critical mistake of ignoring the production calendar. Sourcing headwear isn’t just about what you order and who you order from; it’s also about when. Aligning your production schedule with seasonal demand and major holidays is crucial for maximizing sales and avoiding costly delays.

Here is a sourcing calendar that every hat importer should keep in mind:

- January – March: Prime Sourcing Season for Summer Collections This is the busiest and most critical procurement period of the entire year. Orders for classic summer styles like baseball caps, bucket hats, visors, and straw hats must be placed during this window. This timing allows for production, quality control, and sea freight shipping to ensure your products land in your warehouse in late spring, ready for the peak summer selling season. If you miss this window, you risk delayed shipments that arrive in August when demand is already declining.

- July – September: Peak Sourcing for Winter Headwear As summer demand wanes, the focus shifts to cold-weather items. This is the peak sourcing period for beanies, insulated caps, and other winter headwear. Placing your orders in Q3 ensures the goods are manufactured in the early fall and arrive in your market well before the holiday shopping rush and the first cold snap.

- The Golden Rule: Plan Around Chinese New Year (CNY) This is the single most important timeline consideration of the year. Chinese New Year is not a simple week-long holiday; it causes a near-total shutdown of China’s manufacturing sector for 2-4 weeks, typically between late January and late February.

- The Problem: This is more than just a production shutdown; it’s a full-blown supply chain disruption. In the weeks leading up to the holiday, factories rush to finish orders, which can often lead to a decline in quality control. Simultaneously, a massive pre-holiday rush to export goods creates intense competition for container space and logistics services. As a direct result, both sea and air freight rates can rise sharply, sometimes increasing dramatically as companies are willing to pay a premium to get their products out before the country closes down. This situation often leads to production delays, quality control failures, and severely inflated shipping costs.

- The Solution: To avoid this chaos, your purchase order must be confirmed, and your 30% deposit paid, no later than early December. This gives the factory enough time to procure all needed raw materials before their own suppliers begin to close for the holiday. Any orders placed after this cut-off are at high risk of being delayed until mid-March or even April.

An Insider’s Advice: Treat the Chinese New Year deadline as non-negotiable. I always advise my clients: “Your product might be ready, but if it’s stuck behind a mountain of other orders when the factory reopens in March, you’ve already lost the first part of your selling season.” Plan 45-60 days ahead of CNY, always.

Chapter 3: Hats Customization – The Non-Negotiable Tech Pack

For any custom hats / caps project, the Tech Pack is the single most important document in the entire production process. It is the definitive manufacturing blueprint, serving as a legally binding contract between you and the factory. A well-executed Tech Pack is your primary defense against miscommunication and production errors.

A professional Tech Pack must include the following components:

- Design Schematics (Flats): Clear, detailed drawings of the hat from all angles (front, back, side, interior), with all features and embellishments clearly annotated.

- Bill of Materials (BOM) 3: An exhaustive list of every single component, including:

- Fabric Specifications: e.g., “100% Cotton Twill, 320 GSM.”

- Color Codes: You must use a universal standard, preferably Pantone (e.g., “PANTONE 19-4052 Classic Blue”).

- Component Details: e.g., “Antique brass buckle,” “Woven patch with merrowed border.”

- Size & Measurement Specifications: A detailed chart of all critical dimensions.

- Artwork & Logo Files: High-resolution vector files (.AI or.EPS) for all logos and graphics, with precise placement, size, and technique specified (e.g., “3D embroidery*, 6cm wide, centered on front panels”).

- Construction & Stitching Details: Instructions for specific sewing techniques or structural elements.

- Labeling & Packaging Instructions: Complete designs and content for all interior labels (care, content) and external hang tags.

Expert Warning: A common and costly mistake is to simply mail a reference sample to a factory and expect an exact replication. Without the constraints of a detailed Tech Pack, a factory may substitute materials or alter construction to cut costs, resulting in a final product that fails to meet your quality standards.4

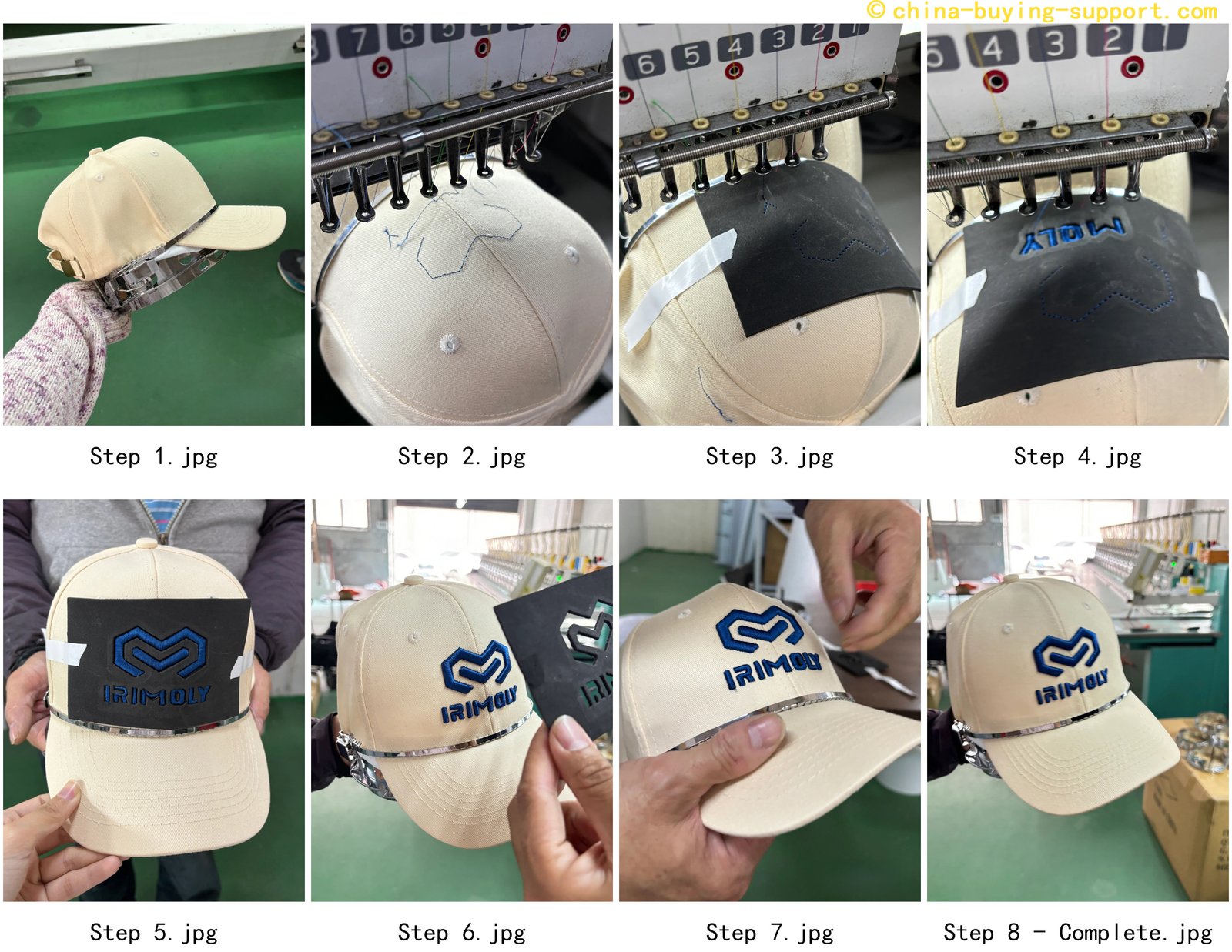

* 3D Embroidery – To better understand the craftsmanship involved in Hats customization, let’s walk through the step-by-step process of a popular technique: 3D Embroidery (3D Puff Embroidery).

This image illustrates the step-by-step process of creating a striking 3D puff embroidered logo on a baseball cap. Starting from the initial hooping and stitching of a placement outline, the image progresses through the application of specialized 3D foam, the precise embroidery of the logo with a high-density satin stitch, the careful removal (weeding) of excess foam, and finally showcases the finished, raised logo. This visual guide highlights the detailed craftsmanship involved in achieving a premium, three-dimensional embroidered effect.

Here’s how we turn a blank baseball cap into a clean, raised logo (3D Embroidery) — step by step:

Step #1. Hooping the Cap

We mount the cap on a cap driver + cap frame. The metal ring locks the bill and crown so the fabric stays flat across the center seam. We align the seam with the machine’s center mark to keep the logo perfectly straight.

Step #2. Placement Check

Before any real stitching, we run a quick trace/placement stitch on the crown. This light outline confirms size and position so the design won’t drift over the seam or hit the visor.

Step #3. Preparing for 3D Puff Embroidery

For the raised logo, we place a piece of puff foam (2–3 mm EVA) over the placement outline and tape the edges. The foam is what gives 3D puff its height.

Step #4. Perforation / Tack-down

We run a short perforation/tack sequence. Tiny stitches punch through the foam and hold it in place exactly where the columns will stitch, preventing shift and blow-outs.

Step #5. Stitching the Logo

Now the fun part: dense satin columns* build the 3D structure. We set proper column width, density, and capping stitches so the thread wraps the foam cleanly and “pops.” Needle height and thread tension are tuned for caps to glide over the center seam without thread breaks. You can see the logo taking shape here.

* What is Satin Column?

A satin column is a fundamental embroidery stitch used to fill narrow shapes like lettering and outlines. It’s created by a series of long stitches that run parallel to each other, passing from one edge of the shape to the other in a tight, zigzag motion. The uniform direction of these long stitches gives satin columns their signature characteristic: a bright, glossy sheen and crisp, well-defined edges, resulting in a slightly elevated, three-dimensional feel.

This is distinctly different from a Tatami or Fill Stitch, which uses shorter, interlocking stitches to cover wider areas, producing a flatter, more textured surface with less reflection. In short, satin columns are ideal for creating bold, lustrous details, while tatami fills are used for covering large surface areas.

Step #6. Foam Removal

Once stitching finishes, we peel away the excess foam by hand. The perforations tear clean.

Step #7. Cleanup and An Eye for Detail (QC)

A machine can do the heavy lifting, but the final touches require a skilled hand. Quality-control inspects every single piece, carefully cleaning up any stray threads and removing tiny bits of remaining foam.

Step #8. Final Quality Check

De-hoop, brush the nap, trim jump threads, and inspect alignment and edge seal. Result: a structured cap with a sharp, durable logo and a bold 3D puff embroidery finish. This meticulous finishing process is what separates a good-looking cap from a great one.

Chapter 4: The Risk Shield – Professional QC & Secure Payments

The most successful importers are, first and foremost, expert risk managers. Establishing robust safeguards during the production and payment phases is non-negotiable.

4.1 The Mandatory Three-Stage Quality Control (QC) System

- Pre-Production Inspection (PPI):

- Before mass production begins, all raw materials and components are inspected to ensure they match the Tech Pack specifications. Typically, your agent will handle this process with the factory and send the results to you for final approval.

- A “Pre-Production Sample” is approved. This sample becomes the gold standard against which the entire production run will be measured.

- During Production Inspection (DPI or In-Line):

- An inspector (or your agent) visits the factory when 15-20% of the order is complete.

- Purpose: To identify and fix any major problems (like incorrect logo placement or a color mismatch) as early as possible, preventing the entire order from being unsaleable. One of my clients once caught a 2.3cm logo placement error on an order of 8,600 premium snapbacks during a DPI, a catch that saved them over $17,000 in potentially unsaleable inventory.1

- Pre-Shipment Inspection (PSI):

- This final inspection occurs when 100% of the goods are produced and at least 80% are packed for shipping.

- Standard: Inspections are typically conducted using the AQL (Acceptable Quality Level) sampling standard. I recommend Level II, 2.5%, which is the industry norm for consumer goods.1 The inspector will check for design, color matching, workmanship, dimensions, packaging, labeling, and overall conformity to the approved sample.

4.2 Secure Payment Structures & Methods

Your money is just as important as your product. Here’s how you protect it 1:

- Safe Payment Tiers:

- New Suppliers: Pay a maximum of 30% as a deposit. The final 70% balance should only be released after you have received a passing inspection report from your third-party QC agent, but before the goods are shipped.

- Established Relationships: More flexible terms, such as 30% deposit, 40% pre-shipment, and 30% upon delivery, can be negotiated over time.

- Large Orders: For transactions exceeding $20,000, consider using a Letter of Credit (L/C). While it comes with more bank fees, it offers the highest level of security for both buyer and seller.1

- Secure Payment Platforms:

- Recommended: Alibaba Trade Assurance provides a robust escrow service and dispute resolution mechanism, offering excellent buyer protection.1

- Warning: Here is a golden rule that could save you from losing your entire money: Never use untraceable payment methods like Western Union or MoneyGram for bulk orders. The reason is simple: these services provide no way to dispute a transaction or get your money back if something goes wrong.1

Chapter 5: The U.S. , EU and Australia Hat Import Checklist: Staying Out of Trouble

Getting your product manufactured and shipped is only half the battle. Ensuring it can be legally sold in the United States is paramount. Failure to comply with U.S. import regulations can lead to customs trouble, fines, and legal risks.

These are the core regulations you must address when importing hats into the target market 3:

5.1 USA

5.1.1 Mandatory Labeling Requirements in US

Under Federal Trade Commission (FTC) rules, all textile products, including hats, must have a permanently affixed label that clearly states 3:

- Fiber Content: e.g., “100% Cotton.”

- Country of Origin: Must be conspicuously marked “Made in China”.

- Manufacturer or Dealer Identity: Your company name or Registered Identification Number (RN).

- Care Instructions: Must use the standardized care symbols outlined in ASTM D5489-96c.3

5.1.2 Children’s Product Safety Regulations

If you are importing hats intended for children 12 and under, you are legally required to comply with the Consumer Product Safety Improvement Act (CPSIA). This involves:

- Mandatory third-party laboratory testing by a CPSC-accepted lab.

- Testing for hazardous substances like lead content and phthalates.

- Issuing a Children’s Product Certificate (CPC) for each shipment.

5.1.3 Other Critical Compliance Areas

- Flammable Fabrics Act (FFA): Ensures the textiles used are not dangerously flammable.3

- California Proposition 65: If selling in California, you must ensure your products are free of the chemicals listed on the Prop 65 list or provide a clear warning label.3

Expert Advice: Integrate all compliance requirements directly into your purchase order and Tech Pack. Make passing all required lab tests a contractual condition before final payment is made. Partnering with a reputable third-party testing laboratory is a wise and necessary investment.

5.2 European Union (EU)

- CE Marking:

- Conventional Fashion Headwear (Hat, Cap, Visor): Generally not required.

- Protective Headwear (PPE): Mandatory certification and CE marking are required for items like industrial safety helmets or professional-grade high-UPF sun hats.

- REACH Regulation (Chemical Safety):

- A mandatory requirement applicable to all materials.

- Products must not contain restricted chemicals above legal limits. Key substances of concern include: Azo dyes, heavy metals (lead, cadmium), and nickel release from metal parts in skin contact.

- Requesting third-party test reports from suppliers is highly recommended.

5.3 Australia

- Mandatory Labelling:

- Country of Origin: Must be labelled, and it must be a permanent label (e.g., sewn-in, not a sticker).

- Care Instructions: Must provide clear instructions for care.

- Fibre Content: Must be accurate to comply with Australian Consumer Law.

- Import Regulations:

- Duties & Taxes: Duties are calculated based on the product’s HS Code, and a 10% Goods and Services Tax (GST) is applied. But there is a very important document to get your import duties to be ZERO – which is CHAFTA Certificate of Origin. For more information, you can click here to read more – you will get: the tariff benefits of ChAFTA, what the origin certificate is, how to obtain it, and other essential details – providing a clear roadmap for Australian importers and wholesalers to make the most of ChAFTA’s advantages.

- Biosecurity: Extremely strict. Headwear made from natural materials (e.g., straw, wood, feathers, some leathers) may face rigorous inspection, fumigation, or other treatment requirements.

Chapter 6: The Final Mile – Optimizing Logistics & Calculating True Cost

With production and inspection complete, the final stage is logistics. Efficient shipping and accurate cost calculation are the final key factors of how much money you make.

6.1 Selecting the Right Shipping Method

- Express Courier (e.g., DHL, FedEx): Best for small, high-value, or urgent shipments (typically under 200 units or 150kg). Fastest transit time (4-7 days) but highest cost.

- Air Freight: A balance of speed and cost for medium-sized shipments that are time-sensitive. Transit time is typically 13-15 days.

- Sea Freight: The most cost-effective option for large, non-urgent orders (generally over 1,000 units). Be prepared for longer transit times (30-45 days).8

6.2 Calculating Your “Landed Cost”

The factory’s FOB (Free on Board) price is only the beginning of your total cost. To accurately project your profit margins, you must calculate your final Landed Cost, which includes 8:

- Product Cost (The factory’s invoice, Ex-work)

- International Freight (Shipping from China to a U.S. port or any other port in your country)

- Insurance

- Import Duties (For cotton hats, the HTS code is typically 6505.00 for the US, with a duty rate around 7-8%)

- Customs & Port Fees (e.g., Merchandise Processing Fee, Harbor Maintenance Fee)

- Customs Broker Fees

- Inland Transportation (From the port to your warehouse)

Expert Advice: Partner with a reputable freight forwarder. They will not only secure more competitive shipping rates than a factory can offer but will also manage the complex web of customs documentation and clearance procedures, saving you significant time and preventing costly errors.

Your Path Forward: The Evolution from Buyer to Strategic Importer

Sourcing hats from China has its challenges, but the payoff can be huge. The secret isn’t just chasing the lowest price; it’s about having a smart, knowledge-based plan.

By mastering product quality, finding the right partners, using precise tools like the Tech Pack, managing risks, and prioritizing legal compliance, you’re no longer just a buyer. You become the architect of your own powerful supply chain.

You now have the expert road-map. It’s time to take that first, smart step and build your brand / business.

Important Terms to Know

- AQL (Acceptable Quality Level): An international statistical standard for sampling and inspecting a production lot to determine its overall quality.1

- BOM (Bill of Materials): A comprehensive list within the Tech Pack that details every single material and component required to build the product.3

- BSCI (Business Social Compliance Initiative): A leading supply chain management system that supports companies to drive social compliance and improvements within their global supply chains.4

- CPSIA (Consumer Product Safety Improvement Act): A mandatory U.S. law that imposes stringent testing and documentation requirements for products intended for children 12 and under.3

- FOB (Free on Board): An Incoterm where the seller is responsible for the goods until they are loaded onto the shipping vessel. The buyer is responsible for all costs and risks from that point forward.8

- GSM (Grams per Square Meter): A unit of measurement for fabric weight and density, serving as a key indicator of material quality.1

- MOQ (Minimum Order Quantity): The smallest quantity of a single product that a factory is willing to produce in one order.11

- Tech Pack: The master blueprint for a product, containing all design, material, measurement, and construction specifications needed for a manufacturer to produce it accurately.3

Our Contact Information as below:

Email:kevin@china-buying-support.com

Phone | WhatsApp:+86 1860 5899 103

Thank you.

Joining Us With 1,200+ Happy Clients Enjoying Buying From China now!

Becoming One of China-Buying-Support family to Get a Easier and Trouble-Free Sourcing and Shipping Service.